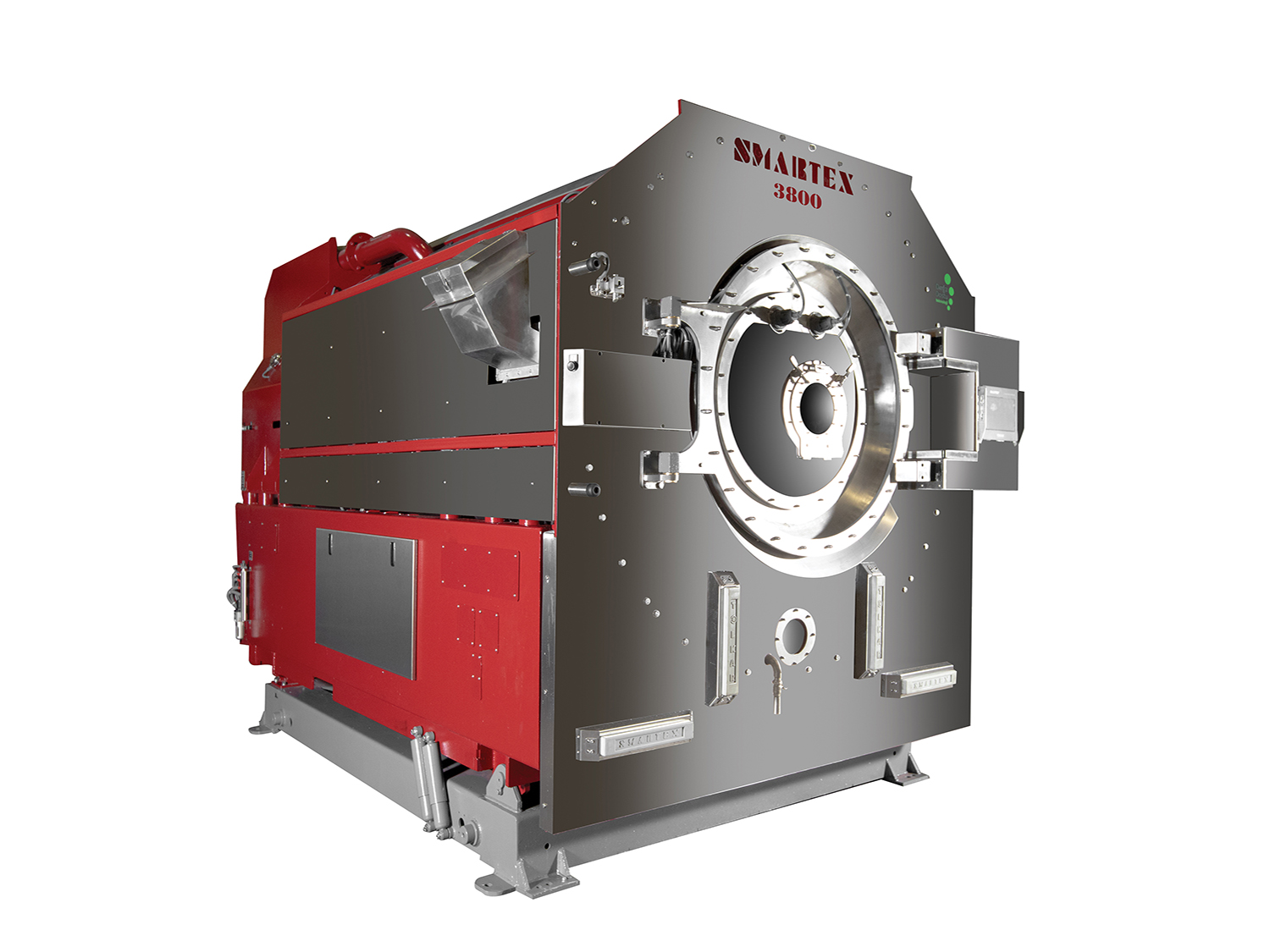

Laundry and textile finishing machine manufacturer Tolkar is launching its data processing and visualisation system for performance measurement and reporting at ITMA 2023. The Turkey-based firm is also demonstrating how it’s leveraged the power of ozone technology in its sustainable textile dyeing, stone washing, denim washing and jeans washing products.

Tolkar’s board member, Ata Karace, said: “We welcome all visitors looking for sustainable production solutions to our booth to see our SMARTEX washing and dyeing machines that reduce natural resource consumption rates by half and our eco-friendly ozone technology products.”

Karace explained that replacing traditional dyeing and washing processes with ozone technology protects water resources, reducing the environmental footprint of textile production.

He continued: “Since 2013, Tolkar started to develop ozone gas washing systems in the textile finishing sector, which was initiated in order to consume much less water – the world’s most valuable resource – and to eliminate heavy chemical wastes left to nature.”

Dissolving ozone gas in water shortens the process time and obtains clean water at the end of the process, reducing the water used in textile washing steps. The method also eliminates the need for many heavy chemicals used in finishing processes, according to Karace.

“Thanks to the Smartex PolyRib ECO Drum system, we have managed to reduce water, chemical and energy consumption by half with MIRACLE, which is a first in the world, and we have created a revolution in this field by adding a new one to our technological developments with the production of Gas Heated Washing machines,” he said.

Smartex is said to have half the water and consumption values of conventional industrial machines.

“Thanks to Smartex washing models, textile manufacturers can produce products with a low carbon footprint,” he explained. “For example, thanks to the Smart Flow Nano Bubble system, some chemical washes can be done almost without using water and zero waste is achieved.”

Tolkar’s R&D teams are continuing to develop products that will improve in technological, ecological and economic terms, with the goal of reducing chemical consumption with ozone as much as possible for a better future.

Karace said Tolkar has established an almost completely unmanned enterprise by controlling all washing, drying, chemical transfer, recipe preparation and reporting from a single centre and providing loading and textile transfers with automatic conveyors.

Tolkar is exhibiting in Hall 9, Booth E205-E206.

Have your say. Tweet and follow us @WTiNcomment